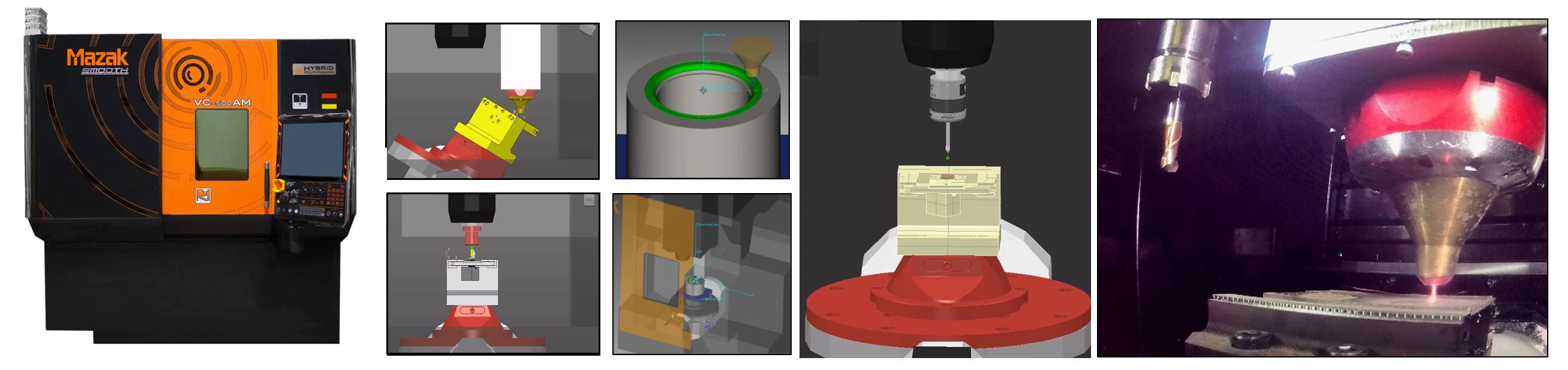

Hybrid Additive Manufacturing Platforms Integration of additive manufacturing into industrial processing workflows must consider the importance of other primary/secondary processes in the realization of a product geometry. Hybrid equipment platforms are capable of integrating additive manufacturing processes with other subtractive, inspection and finishing operations on a single platform. This eliminates the need for registration of part geometries within successive operation steps and opens significant potential for automated, closed-loop fabrication. As these equipment now are readily available, need exists for understanding how the advanced multi-axis capabilities of these machines can be used effectively in practice, including process planning algorithms, process monitoring and control needs and material processing limits. Our group assists partner organizations with exploring and training on state-of-the-art computer aided manufacturing software for hybrid manufacturing, integration of hybrid manufacturing workflows into existing process chains, material compatibility / deposition / machining investigations, and industrial applications development. We leverage a diverse range of materials processing, materials characterization, software-based simulation and cloud-based computing resources to achieve this mission.

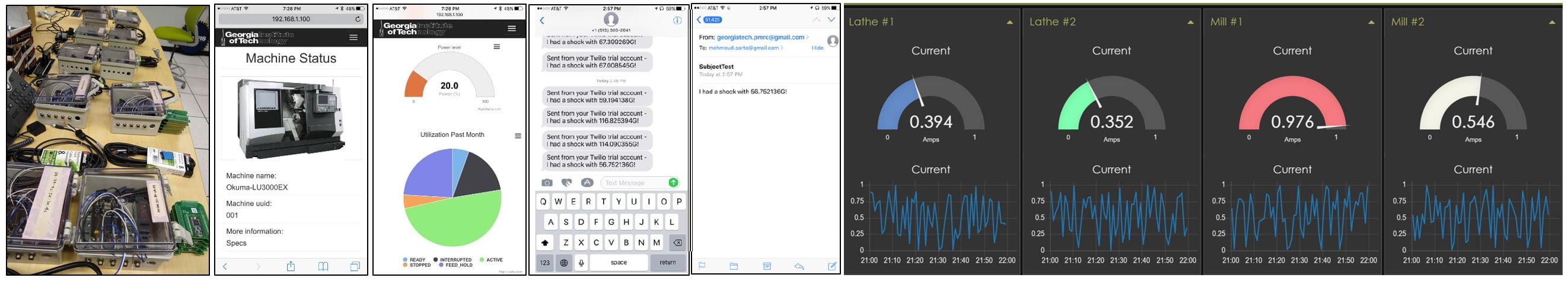

Industrial Internet of Things (IIOT) While large-scale OEM facilities are presently integrating additive processing into conventional manufacturing workflows, the added dimensionality requires significantly more complex process engineering to realize optimality from a manufacturing systems perspective. Realizing this optimality can be accelerated via integrating large data sets generated by on-board manufacturing systems sensors or fog compute based sensor platforms that provide information pertaining to process operations. Opportunities exist for realizing transformative advances in productivity and reductions in energy footprint through highly interleaved additive and subtractive processing via sensors, big data and their integration using commercially available cloud/fog computing platforms. In this focus, we are developing new IIOT sensors, machine learning algorithms and retrofit kits that in the future will change the way that manufacturers and makers produce components through the unrestricted access to process and machine information, as well as the integration of cloud-based machine learning. We leverage state-of-the-art, scalable protocols for secured transmission of manufacturing data and assist our partners with design of effective network architectures and hardware configurations.